Industries

Industries

As concerns about climate change intensify, industries across the globe are recognizing the imperative to reduce their carbon footprints.

In this overview, we explore the necessities and approaches to carbon reduction in key sectors, including Textile and Fashion, Manufacturing in the Automotive Industry, Logistics and Transportation, Construction, Real Estate, and Metal Products. By understanding the unique challenges and opportunities within each industry, we can foster a collective commitment to sustainable practices.

Textile and Fashion Industry

Necessities:

Resource Efficiency

Addressing excessive resource consumption, such as water and energy, throughout the production process.

Supply Chain Transparency

Comprehensively understanding the supply chain (from raw material extraction to manufacturing and distribution) to identify areas of improvement.

Approaches:

Circular Fashion

Adopting circular economy principles by promoting recycling, upcycling, and sustainable sourcing.

Eco-Friendly Materials

Utilizing alternative materials, such as organic cotton, bamboo, and recycled fibers, to reduce environmental impact.

Technology Integration

Implementing innovative technologies for energy-efficient production and waste reduction.

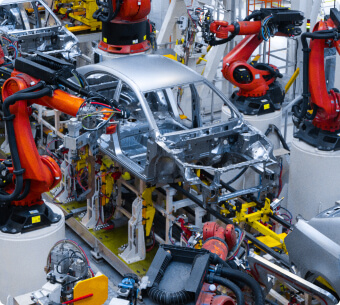

Manufacturing in the Automotive Industry

Necessities:

Emission Reduction

Tackling the carbon emissions associated with manufacturing processes, particularly in welding, painting, and assembly.

Supply Chain Optimization

Addressing emissions across the entire supply chain, including raw material extraction, component manufacturing, and assembly.

CBAM reporting

Submitting carbon footprint reports for imported goods under the CBAM directive.

Approaches:

Electrification

Shifting towards electric vehicle production to reduce dependence on fossil fuels.

Lightweight Materials

Incorporating lightweight materials to enhance fuel efficiency and reduce emissions.

Renewable Energy Integration

Embracing renewable energy sources for manufacturing facilities.

Logistics and Transportation

Necessities:

Fuel Efficiency

Enhancing the fuel efficiency of vehicles, airplanes, and ships to reduce emissions during transportation.

Smart Route Planning

Utilizing technology to optimize transportation routes and minimize fuel consumption.

Approaches:

Alternative Fuels

Exploring and adopting alternative fuels, such as biofuels and hydrogen, to mitigate the environmental impact.

Electric Fleets

Transitioning to electric vehicles for last-mile deliveries and urban logistics.

Collaborative Efforts

Collaborating with suppliers and partners to collectively reduce the carbon footprint of the entire supply chain.

Construction

Necessities:

Energy-Efficient Design

Incorporating energy-efficient design principles to reduce the energy consumption of buildings.

Waste Minimization

Implementing strategies to minimize construction and demolition waste.

Resilient Infrastructure

Building structures that can withstand the impacts of climate change.

Approaches:

Green Building Certifications

Pursuing and achieving certifications such as LEED (Leadership in Energy and Environmental Design).

Smart Technologies

Utilizing smart technologies for energy management, heating, ventilation, and air conditioning (HVAC) systems.

Sustainable Materials

Opting for sustainable and recycled materials in construction projects.

Real Estate

Necessities:

Energy-Efficient Operations

Managing and optimizing energy consumption in buildings throughout their lifecycle.

CO2 footprint for M2 and benchmarking

Emissions-neutral operation

Achieving net-zero for buildings

Approaches:

Green Building Standards

Adhering to green building standards and certifications to ensure sustainability.

Renewable Energy Integration

Incorporating renewable energy sources, such as solar panels and wind turbines, into real estate developments.

Smart Building Solutions

Implementing smart technologies for energy monitoring, lighting, and waste management.

Metal Products

Necessities:

Energy-Efficient Manufacturing

Adopting energy-efficient practices in metal extraction, processing, and fabrication.

Recycling

Promoting the recycling and reuse of metal products to minimize the environmental impact.

Greener Products

Products with reduced GHG emissions.

Reporting to customers, investors and stakeholders

Submitting GHG emissions reports upon requests to ensure transparency.

Approaches:

Closed-Loop Systems

Implementing closed-loop systems that promote the circular economy for metals.

Lean Manufacturing

Adopting lean manufacturing principles to optimize processes and reduce waste.

Carbon Capture and Storage (CCS)

Exploring CCS technologies to capture and store carbon emissions produced during metal manufacturing.

By embracing sustainable practices in these industries, we can not only mitigate their environmental impact but also contribute to a more resilient and responsible global economy. Through innovation, collaboration, and a shared commitment to sustainability, we can forge a path towards a greener future.

If you recognize the importance of stepping onto this path, let CarbonSWOT be your reliable companion. Get in contact with our ESG experts and develop a tailored approach that would precisely cover your business’ unique necessities.